YN-C806 Cement-Based Capillary Crystalline Waterproof Coating

Product Overview

YN-C806 Cement-Based Capillary Crystalline Waterproof Coating is a rigid waterproof material. Its waterproofing mechanism primarily relies on the porosity of the cement base. Under the action of water, the active chemical substances contained in the material penetrate into the concrete capillaries through the carrier H2O, forming water-insoluble crystals within the concrete. These crystals fill the capillary pores, thereby densifying the concrete. The active chemical substances react with unhydrated cement particles to promote cement hydration, forming hydrated crystals that block pores and prevent water from penetrating into the concrete, thus achieving superior waterproofing effects.

Product Features

- It can be used for waterproofing both the upstream and downstream surfaces of concrete structures;

- The construction is seamless, with secondary impermeability and self-repair capabilities;

- It can be applied on damp surfaces, making the construction process simple and easy;

- It has the ability to naturally heal cracks of 0.2-0.4mm;

- It provides protection to steel reinforcement from rusting;

- It can protect concrete from erosion by seawater, wastewater, and some chemical solvents.

Scope of Application

It is widely applicable to walls, floors, or roofs of indoor and outdoor buildings, such as tunnels, dams, reservoirs, power stations, nuclear power stations, pile heads and pile foundations, water storage tanks, and bridges. It can also be used in areas that are constantly submerged in water, such as swimming pools and basements.

Construction Method

-

Prepare the Surface: For larger holes and cracks, first repair and flatten them using patching mortar, then wet the surface with clean water.

-

Apply the Coating: Use a scraper or brush to evenly apply the coating onto the base surface, and check for any defects. Pay special attention to correcting areas such as internal and external corners, wall corners, and edges.

-

Apply Multiple Layers: At least two layers must be applied. Each layer should not be too thick to facilitate curing. The recommended total thickness is approximately 1mm. After completing the first layer, wait for it to dry slightly (until it is no longer sticky to the touch) before applying the second layer. This usually takes 2-3 hours. If the time exceeds this, the first layer of waterproofing must be re-wetted with clean water.

-

Cross-Application for the Second Layer: When applying the second layer, ensure that the brush strokes are at a 90-degree angle to the first layer for complete coverage.

-

Curing After Application: After completion, perform curing by sprinkling water. Avoid stepping on the surface for 24 hours. Proceed to the next step (such as applying a mortar protective layer or tiling) only after the entire waterproof layer is completely dry.

-

Application Temperature: The application temperature should be between 5°C and 45°C.

-

Water-Cement Ratio and Coverage: The water-cement ratio is 1:2.5 to 1:3. The coverage rate is approximately 1.4-1.7Kg per square meter, achieving a thickness of 1.0mm.

Precautions

- Construction should be carried out at room temperature and is not suitable for temperatures below 0°C or in adverse weather conditions such as rain and fog.

- Tap water should be used for mixing and curing; contaminated or unclean water should not be used.

- The construction base surface must be firm and clean, free of floating dust, paint, and other contaminants to facilitate the penetration of the coating and the formation of crystalline structures.

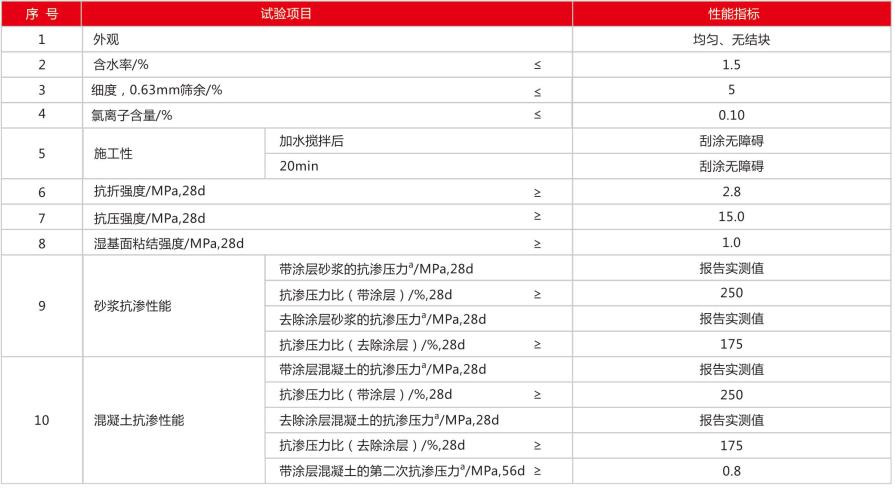

Technical Specifications

Execution Standard: GB 18445-2012