YN-C805 Polymer Cement-Based Waterproof Coating

DETAIL

产品规格

YN-C805 Polymer Cement-based Waterproof Coating

Product Overview

YN-C805 Polymer cement-based waterproof coating is a type of water-based waterproof coating composed of an organic liquid material, which is a combination of polymer emulsions such as acrylate emulsion and ethylene-vinyl acetate copolymer emulsion with various additives, and an inorganic powder material, which is cement. Through rational mixing and compounding, this product belongs to the category of organic-inorganic composite waterproof materials.

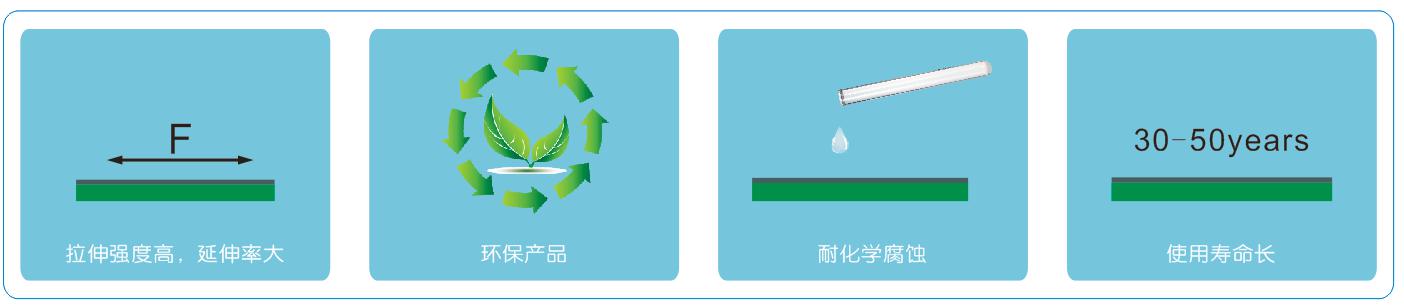

Product Features

- The coating is tough with high strength, strong adhesion, good water resistance, and good weather resistance;

- The coating film is odorless;

- It can be applied to waterproofing walls of various structural layers such as cement and mortar, with strong adhesion;

- Simple construction, fast drying, and short construction period;

- Excellent performance, with good physical and mechanical properties, high and low temperature flexibility, and good aging resistance.

Scope of Application

This product is suitable for waterproofing of building roofs, especially for exterior walls, bathrooms, kitchens, swimming pools, etc., where it provides even better waterproofing effects. It can also be used as an elastic putty for waterproofing exterior wall coatings, enhancing crack resistance, impermeability, and other functions. Additionally, it can serve as a bonding and sealing material for adhering tiles, mosaics, and other purposes.

Construction Method

- Level the roof surface, ensuring it is flat, firm, clean, and free of visible water.

- Before comprehensive construction, strengthen the treatment of ditches, pipes, corners, seams, and other areas.

- During construction, mix the powder material (or 42.5P cement) with the liquid material according to the ratio provided by the manufacturer until evenly mixed. Use the mixed coating within 40 minutes.

- Two methods can be used during construction: roller brushing or scraping. Each layer should be surface-dried for 3-5 hours and fully dried for 12 hours.

- The first coat of the film should be thin, preferably 0.2-0.3mm. Subsequent coats should be 0.4-0.5mm thick. Apply the subsequent coats perpendicularly crossed to the previous coats. Pay special attention to areas with excessive material accumulation to prevent cracking.

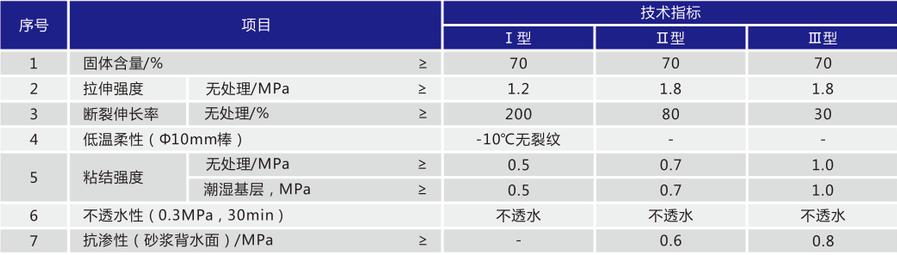

Technical Indicators

Executive Standard: GB/T 23445-2009

REVIEW